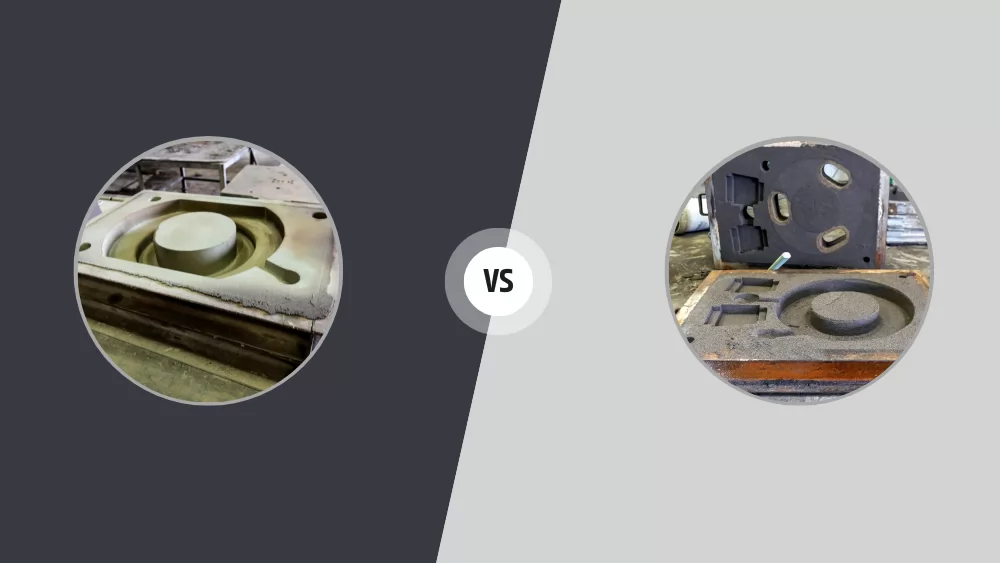

When it comes to metal casting, manufacturers often find themselves comparing shell casting and sand casting to determine which process best suits their project needs. However, it’s not as simple as saying that one is universally “better” than the other. The right choice depends entirely on your part design, production volume, surface finish requirements, and budget. Each method has its own strengths — from the fine precision and smoother surface finish of shell molding to the cost-effectiveness and flexibility of traditional sand casting. In this article, we’ll take a closer look at the key differences between the two processes, their advantages and limitations, and help you make an informed decision on which casting method fits your project best.

1. Shell Molding vs. Sand Casting: Which is Right for You?

Choosing between shell molding and sand casting depends on several measurable factors such as dimensional accuracy, surface finish quality, production volume, and tooling cost. Below we expand on each scenario with practical data ranges and professional insights to help you make an informed choice.

Shell molding is more suitable for you if:

1. You require high precision and surface finish

Shell molding typically achieves dimensional tolerances of ±0.25 mm to ±0.5 mm and a surface roughness (Ra) of 3.2–6.3 µm, which is about 2–3 times smoother than standard sand casting. The process uses resin-coated fine sand cured on heated metal patterns, resulting in dense, rigid molds and consistent part accuracy. This significantly reduces post-machining operations and ensures high-quality surface detail for critical components.

2. You plan for medium-to-high production volumes

While initial tooling costs are higher (ranging from $3,000 to $15,000 depending on part size and complexity), the reusable metal patterns make shell molding economically advantageous for production runs above 500–1,000 pieces. Once tooling is ready, each shell mold can be produced in under 2–3 minutes, making it ideal for stable, repeatable, mid-to-large batch manufacturing.

3. Your part has uniform wall thickness and moderate complexity

Shell molding works best for parts with wall thickness between 3–8 mm and relatively even cross-sections. It handles intricate external features well but can struggle with very thick sections (>30 mm) due to slower heat dissipation, which may lead to shrinkage or internal defects.

4. You want to minimize machining and finishing time

Due to tighter tolerances and smoother as-cast surfaces, shell-molded parts often require 30–50% less machining time. This makes it particularly suitable for components with sealing or mating surfaces where minimal material removal is desired.

Sand casting is more suitable for you if:

1. You are producing small batches or prototypes

Sand casting has low tooling costs — often under $1,000 for basic wooden or plastic patterns — and mold preparation time as short as 1–2 days. It’s the preferred option for 1–100 units or prototype development, where design changes are frequent and flexibility matters more than tooling efficiency.

2. You need to cast large or heavy components

Sand casting supports extremely large castings — from a few kilograms up to several tons. It’s commonly used for large housings, pump bodies, and engine blocks where size or weight makes other methods impractical. Unlike shell molding, there’s virtually no limit to part dimensions.

3. Your part geometry is very complex or has thick sections

Sand molds can accommodate cores, chills, and complex internal cavities with relative ease. It performs well for parts with section thickness over 20 mm and components that require custom gating or feeding systems. Engineers often use sand casting for components where structural integrity outweighs the need for high surface precision.

4. You have a limited budget and low surface finish requirements

Sand casting’s average surface roughness (Ra) is 12.5–25 µm, and dimensional tolerances are typically around ±1.5–3.0 mm. While it produces rougher parts than shell molding, its initial cost is 3–5 times lower. It’s the most economical solution when function and strength are more critical than appearance.

Additional Engineering Considerations

- Tooling cost vs. break-even point: Shell molding becomes more cost-effective beyond ~500 pieces; sand casting remains cheaper below that range.

- Material suitability: Shell molding is ideal for carbon steel, stainless steel, and alloy iron; sand casting suits cast iron, aluminum, and bronze for large structures.

- Shrinkage and solidification control: Sand casting allows more flexible riser and gate design for thick sections; shell molding offers more consistent solidification in thin sections.

- Environmental factors: Shell molding uses phenolic resins (VOC emissions may require treatment); sand casting generates large volumes of waste sand that must be reclaimed or disposed of responsibly.

- Lead time: Shell molding: 2–3 weeks (including tooling); sand casting: 3–7 days for first-off production.

There is no universally “better” process. Shell molding offers higher precision, better surface quality, and is cost-effective for mid- to high-volume production. Sand casting remains unmatched for low-cost tooling, large or heavy castings, and thick-section parts. The optimal choice depends on your part geometry, material, expected quantity, and overall project budget. Conducting a simple cost–quality–lead-time comparison is the best way to determine which process fits your needs.

2. Main Differences Between Shell Molding and Sand Casting

To fully understand the differences between shell molding and sand casting, it’s essential to analyze their performance across multiple dimensions — including precision, cost, efficiency, casting size, material compatibility, and environmental impact. Below is an in-depth, professional comparison of both processes with analytical conclusions for each dimension.

| Comparison Dimension | Shell Molding | Sand Casting |

|---|---|---|

| Surface Quality and Dimensional Accuracy | Excellent. Achieves high surface smoothness with Ra 12.5–25 µm and tight dimensional tolerances (typically ±0.25–0.5 mm). Mold rigidity ensures consistent geometry and fine surface details. | Average. Produces rougher surfaces with Ra 25–100 µm and lower dimensional precision (tolerances ±1.5–3.0 mm). Surface finish depends heavily on sand grain size and compaction quality. |

| Production Cost | Higher tooling investment due to metal patterns (typically $3,000–$15,000), but unit cost decreases sharply as production volume increases. Cost-efficient for medium to large batches. | Extremely low tooling cost (as low as $500–$1,000 using wood or plastic patterns), but per-part cost remains relatively constant. Less economical at high volumes. |

| Production Efficiency | High. Molding cycle is fast (2–3 minutes per shell), tooling lasts up to 100,000 uses, and the process is compatible with automation and mechanized lines. | Lower. Each mold must be remade for every casting; molding and finishing are labor-intensive and slower. Automation is limited due to frequent mold replacement. |

| Casting Size and Weight | Limited. Typically used for small to medium-sized castings under 100 kg. The rigidity of shell molds restricts very large or heavy components. | Almost unlimited. Can produce castings from a few grams to several hundred tons. Preferred for large-scale or heavy-duty castings such as housings, frames, and pump bodies. |

| Material Compatibility | Moderate. Best suited for cast iron, copper alloys, and non-ferrous metals. Not ideal for cast steel due to mold distortion risks at high temperatures. | Highly versatile. Suitable for virtually all casting alloys — including cast steel, iron, aluminum, bronze, and magnesium. Excellent adaptability to different melting temperatures. |

| Minimum Wall Thickness Capability | Better. Can produce thin walls of 3–5 mm with good mold filling due to the fine sand and rigid shell structure. | Inferior. Generally limited to wall thickness above 6 mm. Thin walls risk incomplete filling or cold shuts due to slower metal flow. |

| Environmental Impact | Requires control. Resin-coated sands release phenolic fumes during heating and curing; exhaust treatment and ventilation systems are necessary to meet environmental standards. | Dust intensive. Sand mixing, pouring, and shakeout generate large volumes of silica dust and waste sand, requiring dust collection and reclamation systems to reduce worker exposure. |

Summary: Shell molding excels in precision, efficiency, and thin-wall capability, making it ideal for medium to high-volume production of small and medium-sized precision castings. Sand casting, on the other hand, dominates in flexibility, cost-effectiveness for low volumes, and capability for large, heavy, or complex parts. The final process selection should balance performance requirements, production scale, and total cost of ownership (TCO).

3. Conclusions

Choose Shell Molding First: When you need to produce medium to small cast iron or copper alloy parts in large quantities (for example, tens of thousands of pieces annually) and require high dimensional consistency, excellent surface quality, and reduced machining costs, shell molding is the most economical and efficient choice. Typical applications include automotive crankshafts, brake drums, valve components, and gear blanks.

Choose Sand Casting First: If your production involves small batches, prototypes, or large and heavy castings (such as machine bases or large valve housings), or if you are working with high-melting-point steels, sand casting is the most flexible and cost-effective option. It remains the most widely used and versatile casting process in modern foundry applications.

Consider a Compromise — Other Precision Casting Methods: For smaller parts with extremely complex shapes and precision requirements beyond the capability of shell molding, investment casting (lost wax casting) may be a better solution. Although more expensive, it allows near-unlimited design complexity and exceptional dimensional accuracy.

Final Advice: If you need custom metal parts and are unsure which to choose, feel free to contact us. As metal casting experts, our excellent engineering team can assist you free of charge. Email us now!