A decade ago, "Made in China" might have been synonymous with "low price" in the eyes of international buyers. But today, when German automotive giants, American energy companies, and Middle Eastern infrastructure projects unanimously select Chinese foundry companies for their core supply chain lists, we must acknowledge that a profound transformation has occurred.

This is no longer just about cost advantages; it represents a comprehensive upgrade in quality, efficiency, and reliability. As an industry professional with over a decade of experience in manufacturing, I will reveal the underlying logic behind this phenomenon from five key perspectives.

1. Beyond the Stereotype: From "Price Killer" to "Value Partner"

While cost competitiveness remains a significant factor for overseas customers choosing Chinese foundries, its essence has fundamentally evolved.

Complete Industrial Chain Cost Control:

China possesses a comprehensive foundry industry cluster spanning from raw materials (like rare earths, various alloys), auxiliary materials, equipment manufacturing to energy supply. This cluster effect creates cost optimization that is difficult for any other country to replicate. This goes beyond simple "cheap labor" to represent systematic cost efficiency.

Cost ≠ Compromised Quality:

Where low cost once often meant quality compromises, leading Chinese metal casting manufacturers now reinvest cost advantages into better equipment, stricter quality control, and advanced process R&D, creating a virtuous cycle of "high cost-performance". Customers get exceptional value at reasonable prices.

2. Technological Breakthrough: The "Hard Power" Foundation

If cost is the door opener, what retains top global clients is genuine technical capability.

Dual-Driven by Process and Materials:

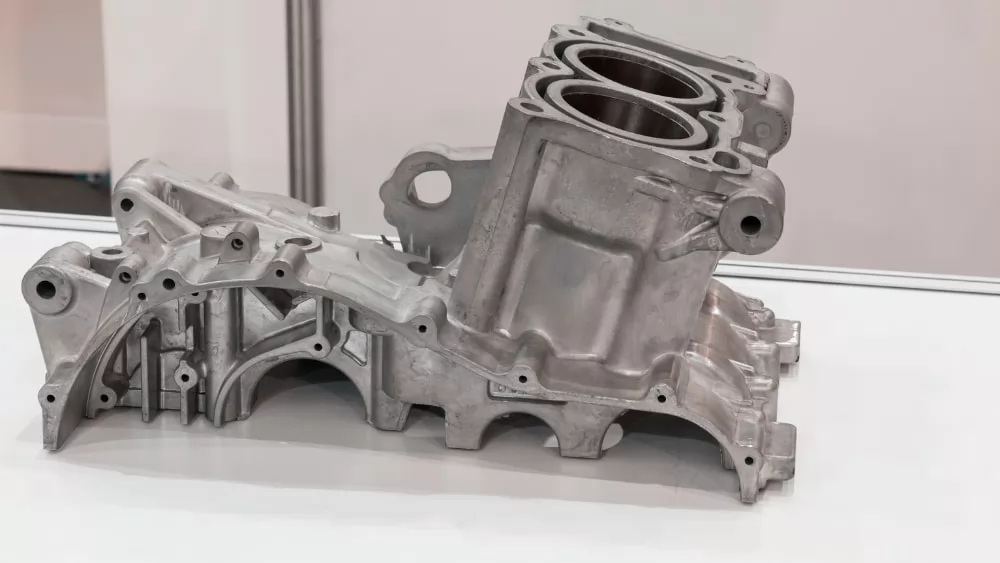

Process Precision: In areas like investment casting (lost-wax casting), large ductile iron castings, and complex thin-wall aluminum alloy casting, leading Chinese companies match the process levels of traditional European and American powerhouses. Key indicators like dimensional accuracy and surface finish meet the most demanding international standards (ASTM, DIN, JIS).

Material R&D: To meet high-end demands from aerospace, new energy vehicles, etc., companies invest heavily in R&D and application of new materials like special alloys and high-temperature alloys, moving beyond simple contract manufacturing.

The "Efficiency Revolution" of Smart and Digital Manufacturing: Visitors to modern Chinese foundry plants are impressed by fully automated melting and pouring lines, robotic grinding units, and full-process data traceability via MES systems. "Dark factories" are becoming reality. This smart transformation greatly enhances production stability, consistency, and delivery speed, addressing the traditional reliance on "master craftsman experience."

Comprehensive Certification Systems Aligned with International Standards: Accessing global supply chains requires playing by the rules. Excellent Chinese casting suppliers typically hold authoritative certifications like ISO 9001 (Quality), IATF 16949 (Automotive), ISO 14001 (Environment), and even AS9100 (Aerospace). These are not just certificates; they signify that management systems and quality control processes are fully aligned with international standards, giving overseas clients solid trust foundations.

3. Beyond Manufacturing: The Underestimated "Soft Power" Advantage

Beyond hard capabilities, unique "soft power" elements form the invisible competitiveness of Chinese foundries.

- Extreme Production Flexibility and Responsiveness: Compared to the relatively fixed capacities and models of overseas factories, Chinese foundries demonstrate remarkable flexibility. Whether for small-batch prototyping, rapid sampling, or urgent order adjustments, they respond quickly. This "customer-oriented" service ethos is crucial for industries with fast product iteration.

- "One-Stop" Solution Capability: More companies now offer not just rough castings but extend services to precision machining, heat treatment, surface treatment, and even component assembly, providing "turnkey" one-stop solutions. This significantly reduces supply chain complexity for customers.

- Service Mentality Forged by Competition: Fierce domestic competition forces companies to excel in service. From pre-project technical communication to transparent progress updates during production (e.g., regular photos/videos) and after-sales support, the entire service experience has become highly professional and attentive.

4. Green Manufacturing and Sustainable Development Capabilities

As global environmental requirements rise, the green transformation of Chinese foundries is remarkable.

- Environmental Investment and Technological Upgrades: To comply with increasingly strict environmental regulations, Chinese casting factories have invested heavily in pollution control, energy consumption reduction, and resource recycling. Many have adopted advanced dust removal equipment, wastewater treatment systems, and energy-saving melting technologies.

- Sustainable Development Philosophy: Leading companies no longer see environmental protection as a burden but transform it into a competitive edge. By developing lightweight castings, using renewable materials, and optimizing processes, they help customers reduce their carbon footprint.

- Compliance with International Environmental Standards: Chinese foundries actively obtain ISO 14001 certification, with some even meeting stringent EU standards like RoHS and REACH, clearing barriers for entry into high-end European and American markets.

5. Global Layout and Supply Chain Resilience

In the post-pandemic era, supply chain stability and resilience have become key considerations for overseas customers.

- Well-Developed Logistics Network: China boasts one of the world's most complete logistics infrastructures, from ports and railways to cross-border e-commerce channels, ensuring products reach global customers quickly and reliably.

- Overseas Localized Services: More Chinese metal casting companies are establishing technical service centers, warehouses, and even overseas plants, providing localized support, after-sales service, and rapid response, greatly enhancing customer experience.

- Supply Chain Risk Management: Through diversified raw material sourcing, safety stock establishment, and digital supply chain management, Chinese foundries demonstrate stronger risk resistance, maintaining stable supply amidst global fluctuations.

Conclusion

The trend of global customers "choosing Chinese foundries" is not temporary; it's based on a clear value formula:

(Superior Cost-Performance + Reliable Technical Quality + Comprehensive System Certification + Green Manufacturing Capability + Supply Chain Resilience) × Extreme Service Flexibility = Irreplaceable Supply Chain Partner Value

Looking ahead, as Chinese manufacturing continues advancing towards greening (eco-friendly casting), moving up the value chain (entering more cutting-edge fields), and globalization (overseas plants), this trend will only strengthen.

Next time you see a precision medical device component or a heavy-duty engineering machinery part, check its origin—it might well be born on the smart production line of a modern Chinese foundry.