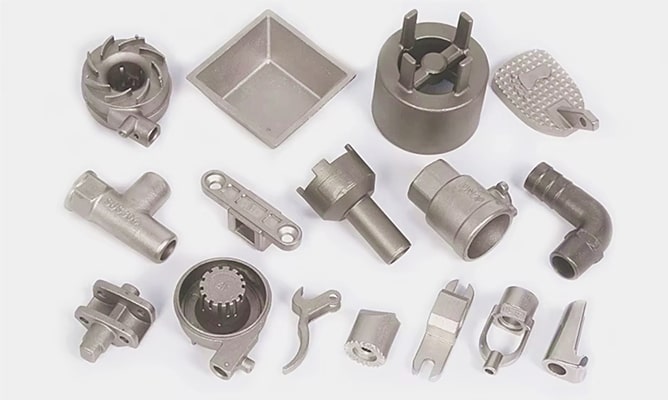

Qianhao Casting has over 32 years of experience. We utilize advanced molding and CNC machining techniques to produce high-performance steel castings with tight dimensional tolerances and excellent mechanical properties.

Our custom steel castings are widely used in the automotive, railway, construction, mining, and agricultural machinery sectors. As a leading steel casting manufacturer in China for over three decades, Qianhao provides accurate cost and lead time estimates for every project.

Our engineering team works closely with our clients from concept to completion, optimizing designs, selecting materials, and ensuring efficient production processes. With in-house heat treatment, machining, and surface treatment capabilities, we are able to provide ready-to-install steel castings tailored to your specific needs.

With 32 years of foundry experience, Qianhao provides complete custom steel casting services — from alloy design to machining and inspection. Our engineering team ensures every project meets precision, durability, and cost-efficiency.

We use precision casting techniques to produce complex steel parts with superior strength, surface quality, and dimensional accuracy.

Carbon steel, alloy steel, stainless steel, and heat-resistant grades — we offer over 30 alloy options to match diverse industry standards.

From design and pattern making to machining and finishing, Qianhao manages every production step under one roof to ensure schedule control and quality.

We deliver accurate dimensions for both small and large components, balancing casting design and post-machining to meet tight tolerances.

Qianhao follows strict inspection and testing protocols to ensure consistent mechanical and chemical properties across every batch.

Our engineering team provides DFM optimization, 3D simulation, and prototyping support to accelerate development and minimize production risk.

Need a custom steel casting solution? Contact Qianhao’s experts for a free consultation and quotation.

High-quality steel castings made with advanced processes tailored to your design and performance requirements

Lost wax casting enables the production of high-precision, complex steel components with excellent surface finish and dimensional accuracy. Ideal for intricate designs, it reduces machining and assembly requirements while maintaining material integrity.

Lost foam casting allows near-net-shape production of steel components with complex geometries and minimal draft requirements. It is suitable for medium-to-large parts requiring high strength and reliable dimensional control.

Shell mold casting provides precise, smooth-surfaced steel components, suitable for medium-sized parts with high dimensional requirements. The method ensures consistent quality and repeatability in production.

Sand casting is a versatile and cost-effective method for producing large or structural steel components. It allows for flexible design, high strength, and efficient production, making it ideal for heavy-duty and construction applications.

High-quality steel materials tailored for diverse casting requirements

Carbon steel is cost-effective and strong, making it ideal for general mechanical and structural components. It offers reliable performance while supporting efficient production of complex shapes.

Alloy steel offers high strength and wear resistance through carefully controlled composition and heat treatment. It is ideal for load-bearing and complex components requiring durability and precision.

Stainless steel provides excellent corrosion resistance, making it suitable for high-precision, durable components exposed to harsh environments. It reduces post-processing while maintaining dimensional stability.

High manganese steel is exceptionally wear-resistant and impact-resistant, making it ideal for heavy-duty and abrasive applications. It maintains toughness under high stress and extends component service life.

_1760430764_WNo_815d443.jpg)

We understand that the quality of steel castings defines your product’s performance and brand reputation. With advanced technology and strict quality control, we ensure consistent and stable results in every piece. Partner with us for worry-free, high-performance castings.

_1760430782_WNo_815d443.jpg)

Our optimized mold design, flexible production, and lean management help lower costs without sacrificing quality. From small trials to large-scale production, we deliver faster — and smarter. Enjoy better pricing and a stronger return on investment.

_1760430801_WNo_815d443.jpg)

We offer end-to-end steel casting services — from design and casting to machining and delivery. Our engineers provide technical support, material advice, and after-sales service to ensure a smooth, efficient, and reliable partnership.

Choose Qianhao, your trusted partner in precision steel castings. With years of foundry expertise, we specialize in producing high-strength carbon steel, alloy steel, and stainless steel castings for automotive, railway, agricultural, and industrial machinery applications.

Get a Quote| Item | Description |

|---|---|

| Material Standard: | GB.ASTM.AISI.DIN.BS.JIS.EN.AS.AAR. |

| Max. Linear Size: | 1500 mm |

| Max. Diameter: | 1200mm |

| Min. Thickness: | 3 mm |

| Weight Range: | 0.10 - 800 kg |

| Dimensional Tolerance: | CT6 - CT10 |

| Surface Roughness: | Ra 6.3 - 25 μm |

First-time ordering steel castings from Qianhao and I'm thoroughly impressed! The quality exceeds our expectations. Excellent craftsmanship and attention to detail. We'll definitely be placing more orders. Highly recommended!

_1760438859_WNo_300d300.png)

Daniela Roberts

Procurement Manager

Qianhao has been our trusted steel casting partner for years. Their competitive pricing, reliable delivery, and consistent quality make them an invaluable supplier. Their team is always responsive and professional. Exceptional service!

_1760438872_WNo_352d352.png)

Ryan Brown

Director

Ten years of partnership with Qianhao speaks volumes about their reliability. As a China-based manufacturer serving global clients, they understand international standards perfectly. Professional team, smooth communication, and always deliver on time.

_1760438887_WNo_352d352.png)

Marcin Pajewski

CEO

Qianhao is a globally recognized manufacturer of high-valued added and complex castings for global industry leaders