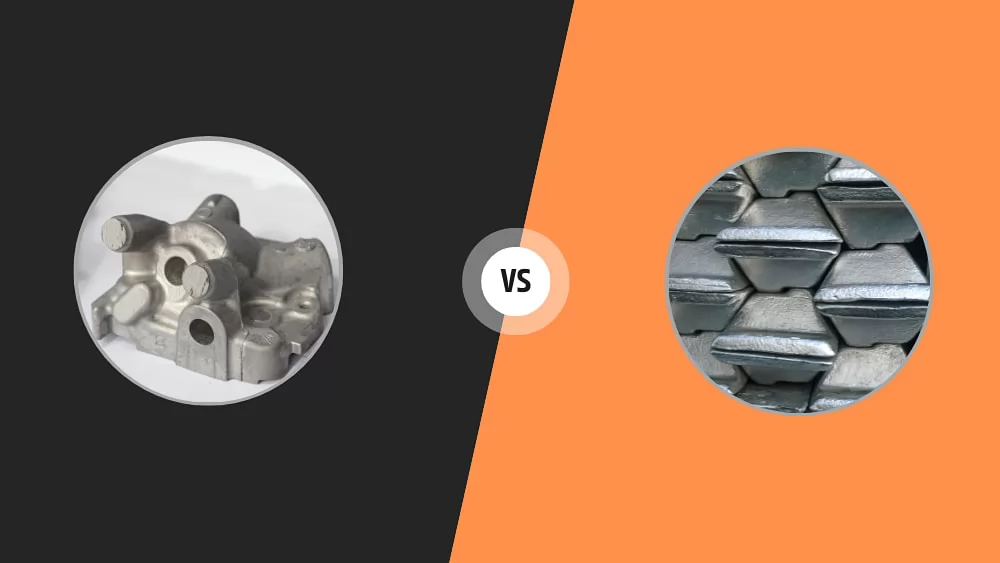

Are you struggling to decide between steel casting and aluminum casting for your upcoming product design? Do you find it challenging to weigh strength versus weight, durability versus cost, or performance versus manufacturability in your material selection process? This is a critical dilemma frequently encountered by design engineers, production planners, and technical buyers across industries.

While both steel and aluminum castings serve as fundamental manufacturing solutions, their distinct material properties dictate completely different application scenarios. The optimal choice fundamentally depends on your component’s functional requirements, operating environment, and lifecycle expectations. Recognizing these differences is essential to avoiding over-engineering, reducing unnecessary costs, and ensuring long-term reliability.

In the following sections, we will break down the key comparisons between steel and aluminum castings — from mechanical strength and weight considerations to corrosion resistance and total cost of ownership — helping you make an informed, confident decision for your specific project.

Summary Table: Steel Casting vs. Aluminum Casting

| Feature | Steel Casting | Aluminum Casting |

|---|---|---|

| Material Cost | Lower raw material cost, but higher processing costs. | Higher raw material cost, but generally lower processing costs. |

| Melting Point | Very High (~1370°C / 2500°F) | Moderate (~660°C / 1220°F) |

| Casting Temperature | Even Higher (~1600°C / 2912°F) | High (~760°C / 1400°F) |

| Fluidity | Poorer; requires more energy and design consideration. | Excellent; can fill complex, thin-walled molds easily. |

| Strength & Hardness | Very High strength, yield strength, and hardness. | Good strength-to-weight ratio, but lower absolute strength and hardness. |

| Weight | Very Heavy (Density: ~7.8 g/cm³) | Lightweight (Density: ~2.7 g/cm³) |

| Corrosion Resistance | Poor (prone to rust); often requires coatings/paint. | Good; forms a protective oxide layer naturally. |

| Machinability | Generally more difficult and abrasive on tools. | Generally excellent and easy to machine. |

| Weldability | Good (with appropriate procedures and filler metals). | Good (with specific techniques and fillers for cast alloys). |

| Common Applications | Heavy-duty applications: mining & construction equipment, railroad wheels, military components, high-temp valves, turbine housings. | Lightweight applications: automotive engines & wheels, aerospace components, marine fittings, electronic enclosures, consumer goods. |

Detailed Comparison of Steel Castings Vs. Aluminum Castings

The choice between steel and aluminum casting is fundamental and is driven by the performance requirements, budget, and design constraints of the final part.

Difference 1. Material Properties: Strength vs. Weight

This is the most significant differentiator.

- Steel Castings are chosen for their exceptional strength, hardness, and wear resistance. They can withstand immense static and impact loads, making them indispensable for components like excavator buckets, crusher jaws, and structural frames for heavy machinery. Their high hardness also makes them resistant to abrasion. However, this comes at the cost of very high density, resulting in heavy parts.

- Aluminum Castings excel in providing a high strength-to-weight ratio. While an aluminum part will not be as strong as an equally sized steel part, it will be less than half the weight. This makes aluminum the undisputed choice for industries where weight reduction is critical, such as aerospace and automotive (e.g., engine blocks, cylinder heads). Aluminum also has better vibration damping characteristics than steel.

Difference 2. Casting Process and Fluidity

The experience of casting these two metals is vastly different due to their melting points and physical behavior.

- Steel Casting is a high-energy, demanding process. Steel's very high melting point requires more robust and expensive furnace linings (often ceramic) and molds (typically sand). The molten steel has poorer fluidity, meaning it does not flow as easily into fine details. This necessitates higher pouring temperatures, larger gates and risers to ensure the mold fills completely, and careful design to avoid defects from premature solidification.

- Aluminum Casting is more forgiving in terms of fluidity. Aluminum's lower melting point makes it easier and cheaper to melt, and it allows for the use of a wider variety of mold materials, including steel permanent molds. Molten aluminum has excellent fluidity, allowing it to fill complex, thin-walled molds and produce intricate details with high dimensional accuracy. This makes it highly suitable for high-pressure die-casting, a very fast production method.

Difference 3. Corrosion Resistance

- Steel has very poor corrosion resistance (rusting) when exposed to moisture and oxygen. Most steel castings require secondary operations like painting, powder coating, or galvanizing to function in corrosive environments.

- Aluminum naturally forms a thin, hard layer of aluminum oxide on its surface when exposed to air. This layer is highly adherent and protects the underlying metal from further corrosion, giving it excellent inherent resistance to atmospheric conditions.

Difference 4. Machinability and Finishing

- Steel is difficult to machine. Its high strength and hardness require more powerful machinery, slower speeds, and specialized cutting tools. It is abrasive and leads to higher tool wear.

- Aluminum is one of the easiest metals to machine. It allows for high cutting speeds, excellent surface finishes, and longer tool life. This can significantly reduce secondary processing time and cost.

Difference 5. Cost Considerations

The cost picture is nuanced.

- Raw Material: Steel is cheaper per pound than aluminum.

- Process Cost: Aluminum casting is generally less expensive. The lower energy requirements for melting, faster cycle times (especially in die casting), and easier machining often make the total cost per part lower for aluminum, despite the pricier raw material.

- Total Cost: For a heavy-duty application where a small, high-strength steel part can replace a much larger, weaker aluminum part, steel may be more cost-effective. However, for high-volume production of lightweight components, aluminum usually wins on overall cost and performance.

When to Choose Steel Castings

Choose steel castings in the following situations:

- When high strength and impact resistance are required: For components that bear heavy loads and impact, such as mining machinery, railroad wheels, and structural parts of heavy equipment.

- When high wear resistance is required: For easily worn parts such as excavator teeth, crusher liners, and conveyor components.

- When operating in high-temperature environments: For components like engine turbine housings, industrial kiln parts, and high-temperature valves, because steel can maintain its strength at high temperatures.

- When weight is not a primary consideration: In applications where component strength is critical and the need for lightweight is not urgent, steel casting is a more economical and effective choice.

Core Trade-off: Choosing steel castings means accepting the disadvantages of being heavier and having higher casting and processing costs in exchange for its unparalleled strength, toughness, and durability.

When to Choose Aluminum Castings

Choose aluminum castings in the following situations:

- When lightweight is a critical requirement: For applications where reducing weight is essential, such as automotive components, aerospace parts, and portable equipment.

- When good corrosion resistance is needed: For parts exposed to atmospheric conditions or corrosive environments where steel would require protective coatings.

- When producing complex, thin-walled shapes: For components with intricate geometries and thin walls that require excellent casting fluidity.

- When high thermal conductivity is required: For heat sinks, engine components, and other applications requiring efficient heat dissipation.

- When high production speed is important: For high-volume manufacturing where die casting processes can achieve fast cycle times.

- When good machinability is valued: For parts that require significant secondary machining operations.

Core Trade-off: Choosing aluminum castings means accepting lower absolute strength and hardness compared to steel in exchange for light weight, excellent corrosion resistance, and better manufacturability for complex shapes.

Conclusion

The choice between steel casting and aluminum casting depends primarily on the specific application requirements. Steel casting, with its superior strength, wear resistance, and high-temperature resistance, is ideal for heavy equipment and harsh working conditions; while aluminum casting, with its lightweight advantages, good corrosion resistance, and superior production efficiency, is particularly suitable for weight-sensitive and structurally complex components.

As a professional casting solutions provider, we recommend that you comprehensively consider factors such as load-bearing requirements, environmental conditions, and production costs in your actual application scenario. We welcome you to discuss your project requirements with our specialists to receive tailored recommendations and manufacturing solutions.

Recommended articles about steel castings vs. aluminum castings:

- Aluminum Casting vs. Steel Casting: Choosing the Right Alloy for Your Cast Products

- Stainless Steel VS Aluminum Castings: When To Use Each

- Choosing the Right Alloy for Your Cast Products: Aluminum vs. Steel Casting

- Aluminum Casting vs Steel Casting

- Aluminum vs Steel Casting for Robotics: Making the Right Choice Between Aluminum and Steel

- Stainless Steel Casting Versus Aluminum Casting

- Aluminium Casting vs. Steel Casting: Which Alloy is Right for Your Product