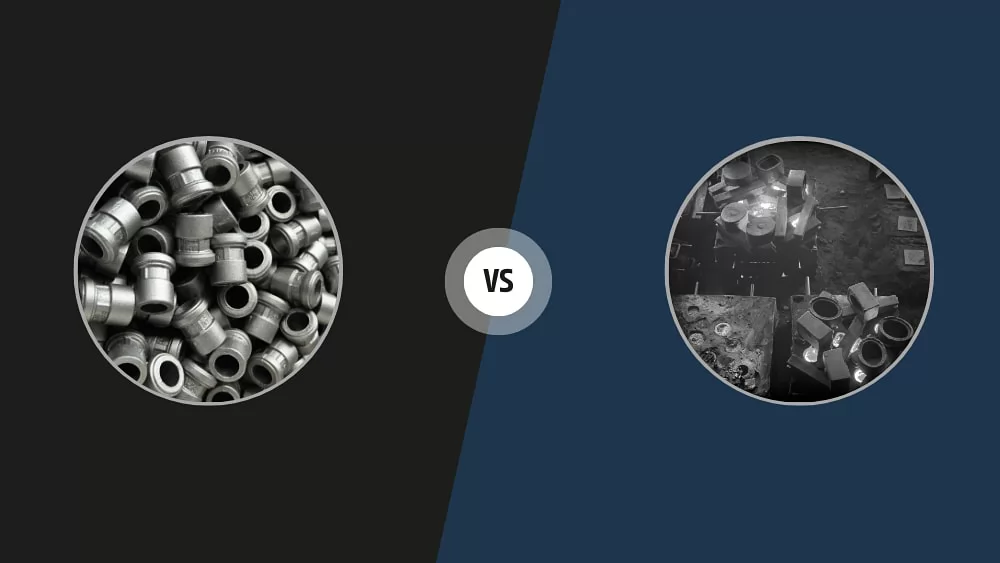

Are you unsure whether to choose steel casting or iron casting for your next manufacturing project? Do you find it difficult to balance performance, cost, and application requirements when selecting the right casting material? This is a common question faced by engineers, procurement teams, and product designers alike.

Both steel and iron castings offer unique advantages, but the best choice depends on how the component will be used, what mechanical properties it must achieve, and the level of durability and safety required. Understanding the key differences will help ensure your final part performs reliably in real working conditions — without overspending or sacrificing quality.

In this article, we will clearly explain the practical selection criteria, compare performance and cost factors, and help you determine which material truly fits your application needs.

| Aspect | Steel Casting | Iron Casting |

|---|---|---|

| Primary alloying element (typical) | Fe + C (carbon typically < 2.14%), plus Mn, Si, Cr, Ni, Mo, etc. | Fe + C (carbon >= 2.14%), commonly with Si, Mn; forms graphite or cementite |

| Microstructure | Ferrite, pearlite, bainite, martensite (depends on composition & heat treatment) | Graphite in matrix (gray, white, malleable) or spheroidal graphite (ductile iron) |

| Mechanical behavior | Generally higher tensile strength and toughness; more ductile | Typically higher compressive strength; brittle if graphite flakes (gray iron); ductile iron is tougher |

| Weldability | Good to moderate (depends on carbon equivalent and heat treatment) | Poor for many cast irons (requires special preheat/interpass/consumables); ductile irons easier |

| Machinability | Moderate — depends on grade and heat treatment | Gray iron: excellent (graphite acts as chip breaker); ductile/white iron: harder to machine |

| Typical casting methods | Sand casting, investment casting, shell mold, centrifugal casting | Sand casting, shell mold, centrifugal, inoculation for graphite control |

| Typical applications | Structural components, pressure parts, gears, shafts, heavy engineering | Engine blocks, pump housings, pipes, machine bases, brake drums |

| Relative cost | Generally higher material cost and often higher processing cost | Typically lower material cost and lower machining cost for gray iron |

Difference 1. What Makes Steel and Iron Different in Composition?

The primary distinction begins with carbon content and how carbon is present in the final microstructure. Steel castings are steels with carbon contents normally below approximately 2.14% (commercial steels commonly range from a few hundredths of a percent to ~1.2–1.5% for many alloy steels). Carbon in steels is predominantly in solution or combined in carbides (cementite) unless deliberately formed as graphite by special treatments.

Cast irons, by definition, contain higher carbon (typically ≥2.14%). That excess carbon leads to graphite formation (flake graphite in gray cast iron, spheroidal graphite in ductile/SG iron, or combined cementite/pearlite in white irons). The graphite morphology controls mechanical properties: flake graphite promotes damping and machinability but reduces tensile strength and ductility; spheroidal graphite preserves ductility and toughness closer to steels.

Difference 2. How Do Their Strength and Toughness Compare?

Steel castings generally have higher tensile strength and significantly greater toughness (resistance to crack propagation) than gray cast iron of similar section and heat treatment. Steels can be heat treated (quenched + tempered, normalized, annealed) to tailor strength, hardness, and toughness across a wide range. As a result, steel castings are preferred where dynamic loading, impact resistance, or tensile performance is critical.

Cast irons frequently offer superior compressive strength and excellent vibration damping because graphite flakes interrupt crack propagation differently than a continuous metallic matrix. However, gray cast iron tends to be brittle in tension; ductile iron (nodular graphite) reduces that brittleness and narrows the mechanical gap with steels.

Difference 3. How Do They Behave During the Casting Process?

Melting range and fluidity differ: many cast irons have lower liquidus and improved fluidity for filling intricate molds, but graphite formation and silicon content must be controlled (inoculation, cooling rate) to achieve the desired graphite type. Steels generally have higher melting/solidification temperatures and require more careful control of deoxidation and cleaning to avoid non-metallic inclusions; steels are more sensitive to hydrogen and shrinkage porosity, so gating and risering designs differ.

Difference 4. Which One Is Easier to Machine or Weld?

Gray cast iron is easy to machine because graphite acts as a built-in lubricant and chip breaker; tool life is often long. Steels, depending on hardness and alloying, can be more demanding to machine and may require tougher tooling and cutting parameters. Welding steel castings is usually straightforward with appropriate preheat/postheat and filler selection. Welding cast iron (especially gray and white irons) is more complex: preheating, slow cooling, and special filler metals are commonly required to avoid cracking; ductile iron and some specialized irons are more weldable.

Difference 5. Which Option Is More Cost-Effective?

Cast irons are commonly less expensive per mass and can reduce post-machining costs for dimensions not requiring high tensile ductility. Steel castings cost more per kilogram and often incur additional heat treatment or inspection costs, but they enable lighter designs (higher specific strength) and match requirements where toughness and fatigue resistance are essential.

Difference 6. How to Decide Which Material Fits Your Application?

Choose steel castings when the component will experience:

- High tensile loads, impact, or dynamic fatigue.

- Requirements for weld repairability or post-heat treatments to achieve precise mechanical properties.

- Designs where ductility and fracture toughness are critical (safety-critical parts, pressure vessels, structural members).

Choose cast iron when the component benefits from:

- Excellent damping (machine tool bases, housings) or high compressive strength.

- Lower cost, high dimensional stability, and good machinability (engine blocks, pump casings).

- Complex shapes where graphite formation and fluidity aid mold filling and reduce shrinkage defects.

Comparison of the Properties of the Two Materials

| Property | Typical Steel Casting Range | Typical Iron Casting Range (examples) |

|---|---|---|

| Carbon content (wt%) | 0.02 – 2.14% | 2.14 – 4.0% (gray/ductile/malleable iron ranges vary) |

| Tensile strength (MPa) | 350 – 800 MPa (common alloy/heat-treated steels ~400–700 MPa) | Gray cast iron: 150 – 350 MPa; Ductile iron: 350 – 700 MPa |

| Yield strength (MPa) | 200 – 600 MPa (depends on alloy & heat treatment) | Ductile iron yield ~200 – 450 MPa; gray cast iron does not have a clear yield point |

| Elongation (%) | 10 – 30% (steels vary widely; low-alloy/heat-treated can be 5–15%) | Gray cast iron: <1 – 2%; Ductile iron: ~5 – 18% |

| Hardness (Brinell, HB) | 120 – 300 HB (depending on heat treatment and alloy) | 160 – 300 HB (white/compacted graphite irons can be higher) |

| Density (g/cm³) | ~7.85 g/cm³ | ~7.0 – 7.3 g/cm³ (varies by graphite content and alloying) |

| Approx. melting/solidus range (°C) | ~1425 – 1540 °C (steel solidus/liquidus vary by composition) | ~1150 – 1300 °C (cast iron liquidus/solidus lower due to higher carbon) |

| Typical applications (examples) | Gears, shafts, pressure parts, forging dies, structural castings | Engine blocks, cylinder heads, pump housings, machine frames, brake drums |

When to Choose Steel Casting vs Iron Casting

| Selection Condition / Requirement | Steel Casting (Recommended When…) | Iron Casting (Recommended When…) |

|---|---|---|

| Mechanical Load Type | High tensile loads, bending loads, fatigue loads, or impact loads. Components must resist cracking under stress. | Mainly compressive loads, low impact environments, stable and uniform loading with minimal fatigue cycles. |

| Required Mechanical Properties | High strength, high toughness, moderate to high elongation, and resistance to brittle fracture are required. | High compressive strength, excellent damping capacity, dimensional stability, or low elongation is acceptable. |

| Component Safety Level | Critical or safety-related components where failure would lead to operational or safety risk. | Non-critical structural components where fracture risk is low and failure consequences are limited. |

| Design Shape/Complexity | Moderate to complex shapes are acceptable, but may require precise gating and risers due to lower fluidity. | Highly complex shapes preferred due to excellent molten fluidity, easier to achieve thin-wall or detailed geometries. |

| Machining Requirements | Machining is acceptable; final precision surfaces or mating fits are needed. | Gray iron is ideal for heavy machining due to graphite lubrication. Ductile iron machinability moderate. |

| Weldability / Repair | Component may require field welding, repair welding, or heat treatment adjustments. | Weld repair is difficult; requires controlled preheat and slow cooling to avoid cracking. Not ideal for frequent welding repairs. |

| Cost Consideration | Higher cost acceptable in exchange for performance and reliability. | Cost efficiency is a priority. Large quantities or large-sized castings benefit from lower cost per unit. |

| Typical Application Examples | Mining equipment, cranes, high-pressure valves, pump impellers, load-bearing gears, connecting rods. | Engine blocks, pump housings, brake drums, machine frames, pipe fittings, municipal castings. |

Detailed Guidance: When to Choose Steel Casting

Choose steel casting when the design requires a material that can withstand high stress, impact, or cyclic fatigue without fracturing. Steel has higher tensile strength and much greater toughness than most cast irons, which makes it suitable for components that operate under unpredictable or dynamic loading conditions.

You should choose steel casting if:

- The part is part of a load-bearing structure or transmits mechanical force.

- The component may be subjected to rapid load changes or vibration.

- The part must be weldable, repairable, or heat-treatable to adjust final performance.

- Failure of the component would cause safety or operational risks.

Detailed Guidance: When to Choose Iron Casting

Choose iron casting when cost, structural stiffness, vibration absorption, and ease of manufacturing are more critical than tensile strength and ductility. Gray cast iron excels at vibration damping due to its graphite structure, and ductile iron provides a balance between toughness and cost efficiency.

You should choose iron casting if:

- The component mainly experiences compressive loads or static support.

- Vibration control or noise reduction is important (e.g., machine beds).

- The part has complex geometry benefiting from iron’s high molten fluidity.

- Production cost must be controlled, especially in high-volume manufacturing.

Quick Engineering Decision Summary

- If the part must resist tensile stress, impact, or fatigue → choose Steel Casting.

- If the part must provide cost efficiency, dimensional stability, and damping → choose Iron Casting.

- If you need a performance compromise → consider Ductile Iron, which provides higher toughness than gray iron at lower cost than steel.

Conclusion

In summary, the choice between steel casting and iron casting depends on the performance requirements, cost considerations, expected loading conditions, and whether post-processing such as welding or heat treatment will be required. Steel castings are best suited for applications where strength, toughness, and reliability under dynamic or impact loads are essential. Iron castings, on the other hand, provide excellent manufacturability, cost-effectiveness, and vibration damping performance, making them ideal for housings, bases, and components under mainly compressive or stable loads.

If your project requires high-strength, safety-critical, or load-bearing steel cast components, we can help. For professional steel casting solutions, customized casting support, and reliable manufacturing services, please contact Qianhao. We are ready to assist you from material selection to final machining and inspection, ensuring performance and quality in every part.