As a leading sand casting company, we deliver proven foundry solutions helping automotive, heavy equipment, energy, and marine industries overcome production challenges. Our sand casting services enable cost-effective manufacturing of large and complex metal components with versatile material options, from iron and steel to cast iron and alloy steel. Explore case studies demonstrating sand casting capabilities from single-piece prototypes to high-volume production.

Our comprehensive manufacturing process ensures the highest quality standards through 6 carefully orchestrated steps. From initial design conception to final delivery, each phase is meticulously planned and executed to deliver exceptional results that meet and exceed industry expectations.

Creating a mold is the first step in the sand casting process. Each casting needs a mold. A sand mold is formed by putting the sand into each half of the mold. The sand is stacked around the pattern, which is a replica of the shape of the casting. When the pattern is removed, the cavity forming the casting remains. Any internal features of castings that cannot be formed by the pattern are formed by separate cores made of sand before forming the mold. The mold-making time includes positioning the pattern, packing the sand, and removing the pattern. The mold-making time is affected by the size of the part, the number of cores, and the type of sand mold. Lubricant is typically applied to the surface of the mold cavity to facilitate removal of the casting. The use of lubricants also improves the flow of the metal and can improve the surface finish of the castings. The lubricant used is selected based on the temperature of the sand and the molten metal.

After the mold is made, it must be prepared to pour the molten metal. First, the surface of the cavity is lubricated in order to remove the castings after casting. Then, the core is positioned and the mold halves are closed and securely clamped together. It is necessary to keep the mold half sealed to prevent any loss of material. The molten metal is kept at the set temperature in the furnace. After the mold is clamped, the molten metal can be cast from the holding vessel in the furnace and poured into the mold. Pouring can be done manually or by automated machines. Sufficient molten metal must be poured to fill the entire cavity and all channels in the mold. Filling time is very short, to prevent the early curing of any part of the metal.

Once poured into the mold, molten metal begins to cool and solidify. When the entire cavity is filled and the molten metal solidifies, the final shape of the casting is formed. Until the end of cooling time, the mold can be opened. The cooling time required can be estimated from the wall thickness of the casting and the temperature of the metal. Most of the possible defects are the result of the solidification process. If some molten metal cools too quickly, the part may shrink, crack or incompletely. Precautions can be taken when designing parts and molds.

After a predetermined set time, the sand mold can simply be broken and the castings removed. This step, sometimes referred to as getting rid of sand, is usually shaken by a vibrating machine and burned out of the bottle. Once removed, the castings may have some sand and oxide adhering to the surface. Blasting is sometimes used to remove residual sand, especially from the inside surface, and to reduce the surface roughness.

During cooling, the material from the mold channels solidifies on the part. These extra material must be manually trimmed by cutting or sawing or using a trimming machine. The time it takes to trim excess material can be estimated from the size of the casting. Larger castings require longer dressing times. Waste from this trimming is discarded or reused during sand casting. However, it may be necessary to remediate appropriate chemicals for scrap before it is used in conjunction with non-recycled metals.

High-quality materials tailored for versatile sand casting applications

Grey iron is widely used in sand casting due to its excellent fluidity, castability, and vibration damping properties. It allows production of large and complex components with minimal defects and good surface finish.

Alloy steel in sand casting offers high strength, toughness, and wear resistance. With proper heat treatment, it meets demanding mechanical and structural requirements for industrial applications.

Carbon steel is commonly used in sand casting for structural and mechanical components. It offers an excellent balance of cost, strength, and toughness, making it suitable for diverse industrial applications.

Relying on powerful and matchless machining finish capabilities, our company expand the product lines and is committed to manufacturing and supplying iron and steel castings made by various casting methods, forgings and profile machined parts.

Get a Quote| Item | Description |

|---|---|

| Material Standard: | GB.ASTM.AISI.DIN.BS.JIS.EN.AS.AAR. |

| Max linear Size(W*C*H): | 1500mm*1500mm*1500mm |

| Casting Weight Range: | 5-2500kgs |

| Casting Dimension Tolerance: | CT10-12 |

| Casting Surface Roughness: | Ra25um |

Qianhao Group offers tailored sand casting solutions to meet diverse industry requirements, providing one-stop services from mold preparation to precision finishing.

For sand casting orders we offer quick turnaround: small batches can be delivered in 15 days, large production runs in 30 days, and urgent projects can be expedited to help you meet critical deadlines.

We provide complete sand casting services — from pattern design, mold and core making, through metal melting, pouring, heat treatment and finishing — ensuring consistent quality for parts of all sizes.

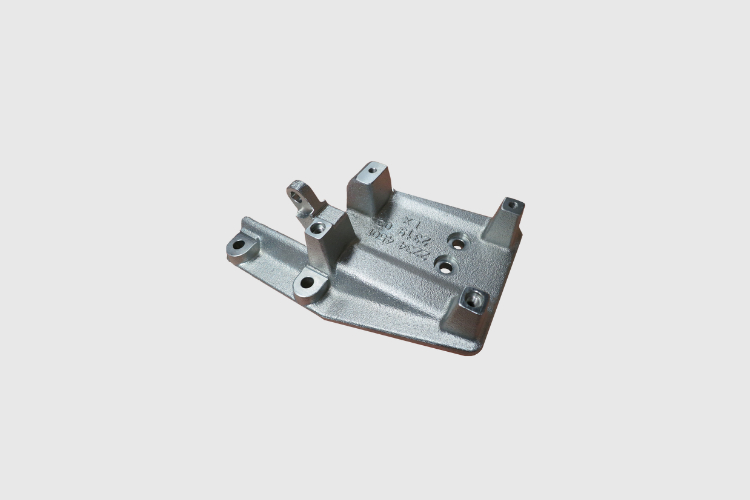

Our sand casting capability delivers durable and accurate castings with reliable performance, making it ideal for automotive, railway, construction machinery and industrial applications.

Qianhao is a globally recognized manufacturer of high-valued added and complex castings for global industry leaders