QIANHAO Corporation is committed to providing products and services that consistently meet our customers' expectations of quality and value. We continually monitor and improve our processes as a means to ensure overall customer satisfaction, achieve our quality objectives, and share best practices.

Quality is always the highest priority at QIANHAO. We at ForceBeyond strive to

meet and exceed all customer requirements and expectations and provide

on-time delivery of defect-free castings, forgings and precision machined parts.

Our commitment to continuous improvement means great value is placed on

teamwork, education, training, and prevention-oriented techniques across all

possible aspects of company operations.

We and all our partner manufacturers are typically ISO 9001 and/or ISO 14001 and/or IATF 16949 certified. Our customers rely on us to deliver world class quality products. Our standard operating procedure for all customers incorporates the automotive PPAP (Production Part Approval Process) quality system for part qualification.Our quality assurance technicians verify every lot of parts to ensure it meets our customers' high standards.

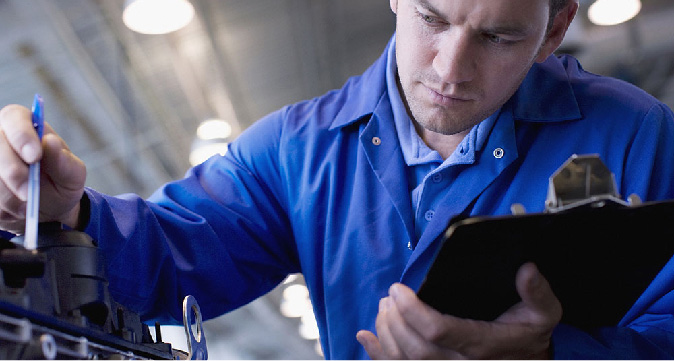

QIANHAO incorporates a robust quality plan to inspect and verify every lot. Our

quality assurance professionals maintain the highest standards of training and

education. Prior to exit-factory, all material and dimensional inspections are

completed and certified.

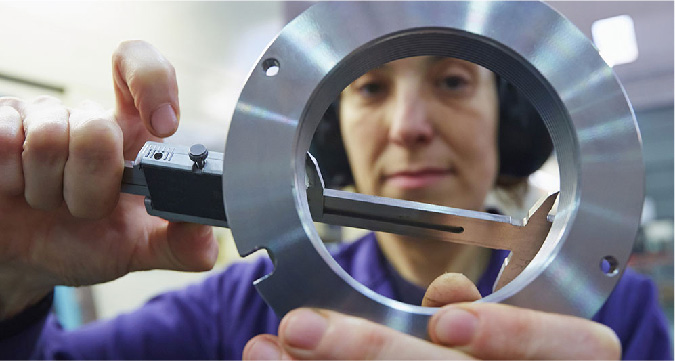

Equipping with the latest in inspection technology and precision metrology,

our quality team is able to obtain accurate data and pass that information on

to our customers whenever required. We offer our customers: First-Article I

nspection Reports, SPC Data, PPAP Reports and Final Inspection reports. We

also maintain a database with a full complement of quality records for

immediate retrieval when required.

Qianhao is a globally recognized manufacturer of high-valued added and complex castings for global industry leaders