Metal casting materials are primarily metals and alloys that can be melted at high temperatures and poured into molds to form specific shapes. Once solidified, they maintain excellent mechanical properties such as strength, hardness, and wear resistance, making them suitable for a wide range of industrial applications. Common casting materials include iron, steel, aluminum, and copper alloys, each selected for its unique performance characteristics.

Product designers rely on material properties to ensure functional reliability and structural integrity. Foundry engineers must precisely control melting, pouring, and cooling parameters according to the thermal behavior of the chosen alloy to optimize production. Pattern and mold designers need to consider material shrinkage, flow, and solidification when developing mold structures. Quality control specialists analyze material defects to trace the root causes of casting issues.

Qianhao Foundry’s casting experts and technical staff have more than 32 years of experience in metal casting production and can fully understand our customers’ requirements, ensuring durable, accurate, and cost-effective solutions.

High-quality materials tailored for diverse casting applications

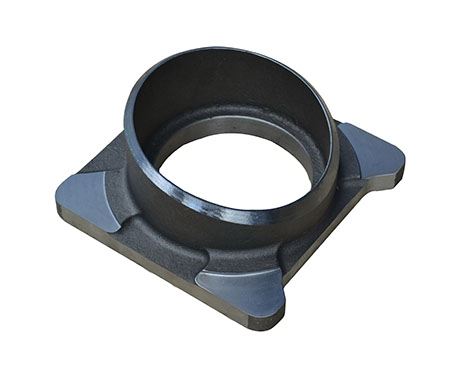

Stainless steel castings are widely used for parts requiring high corrosion resistance and durability. They maintain excellent mechanical properties even in harsh environments, making them ideal for critical industrial applications.

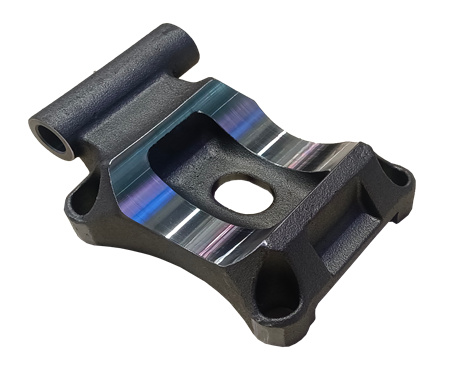

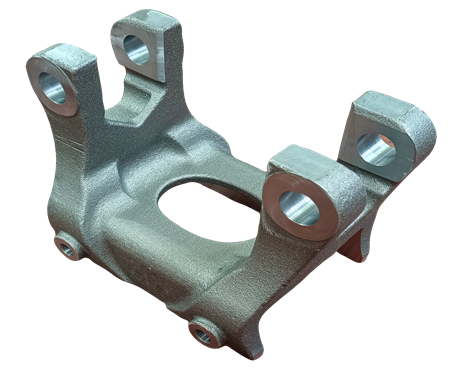

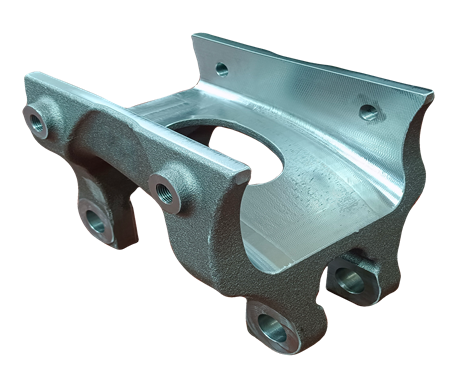

Alloy steel castings offer enhanced strength, hardness, and wear resistance through customized compositions and heat treatment. They are suitable for parts operating under high stress and demanding conditions.

Carbon steel castings combine high strength with cost-effectiveness. They are one of the most widely used materials in metal casting, suitable for both structural and general mechanical applications.

Iron castings, including grey iron and ductile iron, are widely used thanks to their excellent castability, vibration damping, and wear resistance. They are essential for large and heavy-duty industrial components.

Qianhao Foundry has obtained ISO 9001 and TS 16949 certifications, and is capable of undertaking various metal casting projects.

Qianhao is a globally recognized manufacturer of high-valued added and complex castings for global industry leaders