We are equipped with modern casting production lines and multiple heat treatment and subsequent machining production lines, providing one-stop solutions, from wax model manufacturing, ceramic shell preparation to melting and pouring and precision grinding and polishing, ensuring that each lost wax casting has extremely high dimensional accuracy and surface finish.

The investment casting process consists of several steps: metal die construction, wax pattern production, ceramic mold creation, pouring, solidification, shakeout, and cleanup.

The wax pattern and ceramic mold are destroyed during the investment casting process, so each casting requires a new wax pattern. Unless investment casting is being used to produce a very small volume (as is common for artistic work or original jewelry), a mold or die from which to manufacture the wax patterns is needed. The size of the master die must be carefully calculated; it must take into consideration expected shrinkage of the wax pattern, the expected shrinkage of the ceramic material invested over the wax pattern, and the expected shrinkage of the metal casting itself.

The number of wax patterns always equals the number of castings to be produced; each individual casting requires a new wax pattern. Hot wax is injected into the mold or die and allowed to solidify. Cores may be needed to form any internal features. The resulting wax pattern is an exact replica of the part to be produced. The method is similar to die-casting, but with wax used instead of molten metal. Hot wax is injected into a mold or die and allowed to solidify, resulting in a wax pattern that is an exact replica of the part to be produced.

A gating system (sprue, runner bars, and risers) is attached to the wax mold. For smaller castings, several wax patterns are attached to a central wax gating system to form a tree-like assembly. A pouring cup, typically attached to the end of the runner bars, serves to introduce molten metal into the mold. The assembled “pattern tree” is dipped into a slurry of fine-grained silica. It is dipped repeatedly, being coated with progressively more refractory slurry with each dip. Once the refractory coating reaches the desired thickness, it is allowed to dry and harden; the dried coating forms a ceramic shell around the patterns and gating system. The thickness of the ceramic shell depends of the size and weight of the part being cast, and the pouring temperature of the metal being cast. The average wall thickness is approximately 0.375 in. (9.525 mm). The hardened ceramic mold is turned upside down, placed in an oven, and heated until the wax melts and drains away. The result is a hollow ceramic shell.

The ceramic mold is heated to around 800-900°C. The heating process further strengths the mold, eliminates any leftover wax or contaminants, and evaporates water from the mold material. Molten metal is poured into the mold while it is still hot – liquid metal flows into the pouring cup, through the central gating system, and into each mold cavity on the tree. The pre-heated mold allows the metal to flow easily through thin, detailed sections. It also creates a casting with improved dimensional accuracy, as the mold and casting will cool and shrink together.

After the mold has been poured, the metal cools and solidifies. The time it takes for a mold to cool into a solid state depends on the material that was cast and the thickness of the casting being made.

Once the casting solidifies, the ceramic molds break down, and the casting can be removed. The ceramic mold is typically broken up by machine. Once removed, the individual castings are separated from their gating system tree using manual impact, sawing, cutting, burning, or by cold breaking with liquid nitrogen.

Finishing operations such as grinding or sandblasting are commonly employed to smooth the part at the gates and remove imperfections. Depending on the metal that the casting was poured from, heat treating may be employed to harden the final part.

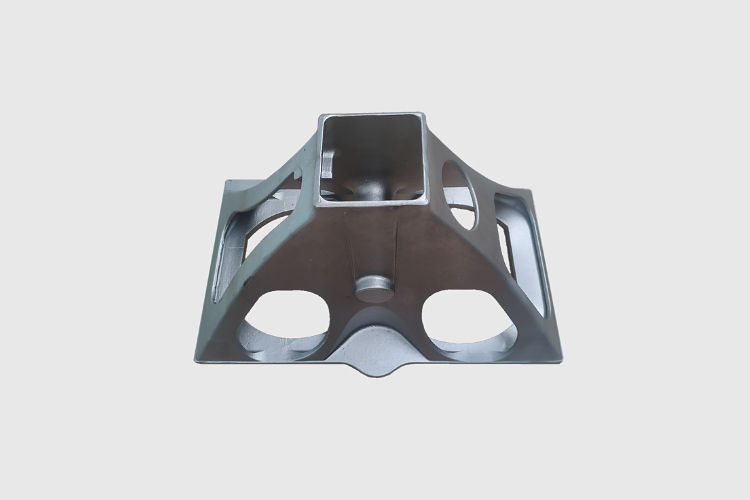

High-precision casting services tailored for complex and detailed components

Stainless steel in lost wax casting provides superior corrosion resistance, strength, and aesthetic surface finish. It is widely used in industries requiring hygiene, durability, and precision.

Carbon steel in lost wax casting is cost-effective and offers excellent mechanical properties. It is commonly chosen for structural and industrial components requiring strength and toughness.

Alloy steel lost wax castings combine toughness, durability, and performance. They are well-suited for high-stress industrial and automotive applications with strict quality requirements.

Relying on powerful and matchless machining finish capabilities, our company expand the product lines and is committed to manufacturing and supplying iron and steel castings made by various casting methods, forgings and profile machined parts.

| Items | Description |

|---|---|

| Material Standard: | GB.ASTM. AISI. DIN. BS. JIS. EN. AS. AAR. |

| Min Thickness: | 3mm |

| Casting Dimension Tolerance: | CT6-CT8 |

| Max linear Size: | 1000mm |

| Max Diameter Size: | 600 mm |

| Casting Weight Range: | 0.1~80kgs |

| Casting Surface Roughness: | Ra6.4-12.5um |

Years of Expertise

Production capacity

Factory Area

Number of employees

We provide high-precision lost wax casting services for complex metal parts, ensuring ±0.1mm tolerance to meet the needs of the aerospace, medical and jewelry industries.

From 3D model optimization to post-processing, we provide one-stop service, including mold design, surface finishing and quality inspection, and full technical guidance.

Small batches are delivered in 15 days, large batches are completed in 30 days, and urgent orders can be expedited to help you seize the market opportunity.

Qianhao is a leading and globally recognized brand for complex and high-tech castings in the area of automobile, rail, construction equipment, material handling equipment and agricultural machinery.

Qianhao is a globally recognized manufacturer of high-valued added and complex castings for global industry leaders