This guide introduces the Top 10 Precision Investment Casting Companies in China (2025 List), helping you identify reliable suppliers known for their technical expertise, consistent quality, and professional export capabilities.

This 2026 revenue ranking highlights the world’s top steel casting companies based on publicly available financial data, industry influence, and manufacturing scale.

At its core, shell casting—also known as shell moulding casting—is a type of precision casting process where a thin but strong shell mold is created using resin-coated sand.

In this article, we’ve selected the Top 10 Lost Wax Casting Jewelry Suppliers of 2026 — companies that stand out for their reliability, innovation, and commitment to supporting jewelers with the best casting tools and materials available.

This article explaining the shell mold casting process is intended to help you make an informed decision when selecting a casting technique for your manufacturing needs.

Are you currently searching for a dependable lost wax casting supplier that can deliver consistent quality, precision tolerances, and stable production capacity?

Are you looking for a reliable lost wax casting supplier in the UK for your next precision metal project? This article will answer all your questions!

Are you planning to find Chinese metal casting suppliers in 2026 to optimize production costs and enhance supply chain competitiveness? Click here to learn more.

In this guide, we introduce top steel casting companies in China, their capabilities, and buyer-focused insights to help you make informed decisions.

Are you struggling to find a reliable investment casting partner in the USA that can deliver precision, quality, and timely production? This article will help you!

Learn everything about steel casting in 2026 — from process types and material options to industrial applications and pricing factors.

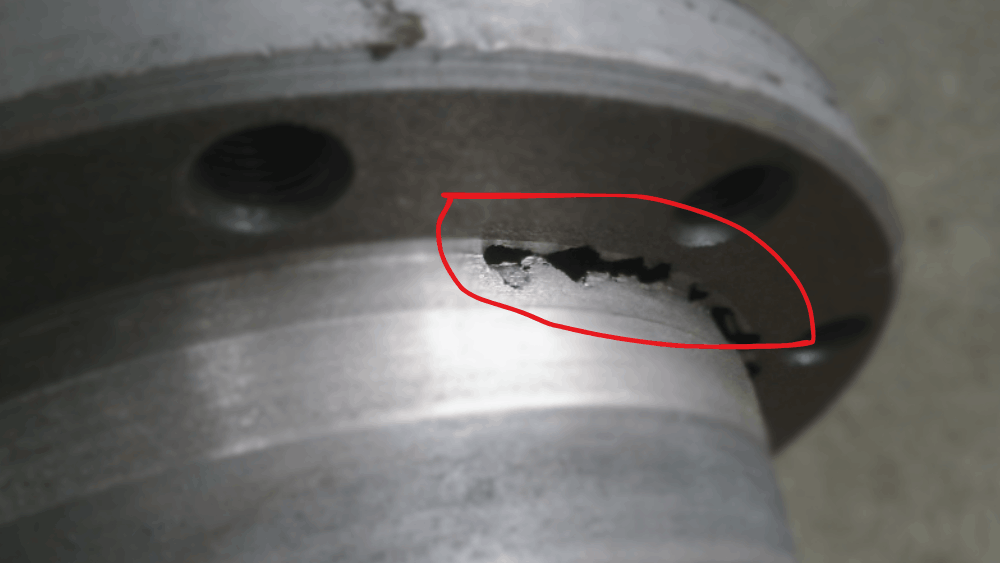

Learn how to distinguish shrinkage cavities from shrinkage porosity in metal castings. This guide provides practical field identification tips, inspection insights, and decision-making advice for foundries, quality engineers, and buyers.

Discover typical prices for metal casting services in China. Learn how factors like material, casting method, and volume affect cost. Get tips to budget and source effectively.

Understanding common casting defects, including low-pressure casting defects, shrinkage cavities, cold shuts, cracks, and sand adhesion, is crucial for engineers and manufacturers aiming to improve casting quality and reduce scrap rates.

Metal manufacturing processes define how raw metal materials are transformed into functional parts and components used across industries such as automotive, construction, energy, and heavy equipment.

How much does overseas metal casting actually cost—and why do quotations for the “same” casting vary so dramatically from one supplier to another?

This guide will break down what metal casting is, how it works, and how professional foundries control each stage to produce strong, reliable metal components.

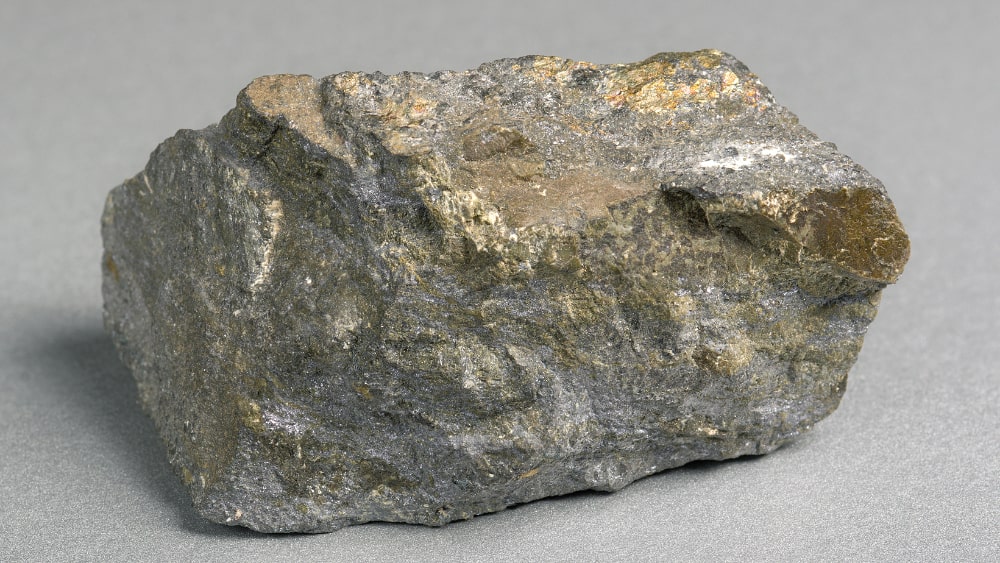

This material is manganese steel, and the process of shaping it into various complex forms is manganese steel casting.

Melting steel for casting is a complex industrial process that requires extremely high temperatures, specialized equipment, and precise control over chemical composition.

Yes, stainless steel can be cast—but it requires specific techniques and considerations due to its unique metallurgical properties. Here’s a breakdown of how, why, and the key factors involved

*We respect your confidentiality and all information are protected.

Qianhao is a globally recognized manufacturer of high-valued added and complex castings for global industry leaders